Our Services

Validation & FAT

Validation & FAT

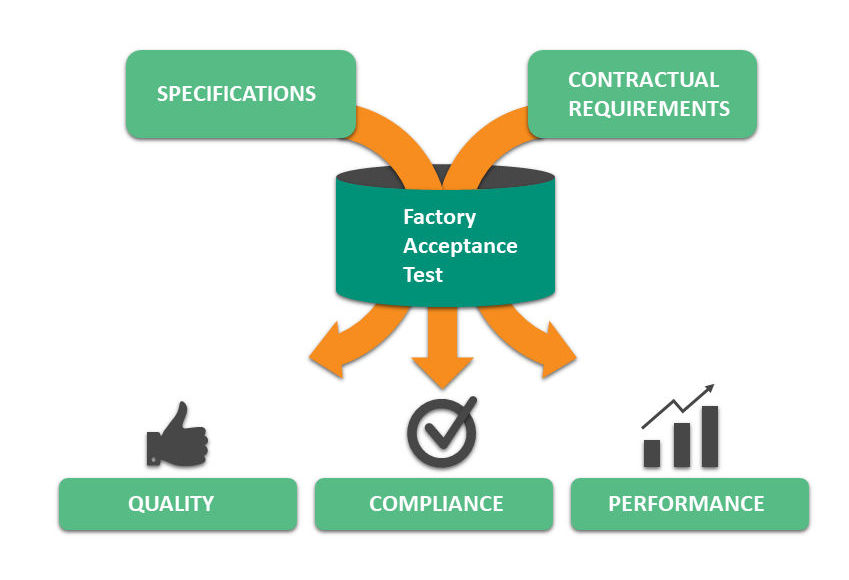

Factory Acceptance Test (FAT)

The Factory Acceptance Test (FAT) is a process that evaluates the equipment after the assembly process by verifying that it is built and operating in accordance with design specifications. It is done to ensure that the equipment comply with all the cGMP requirements.

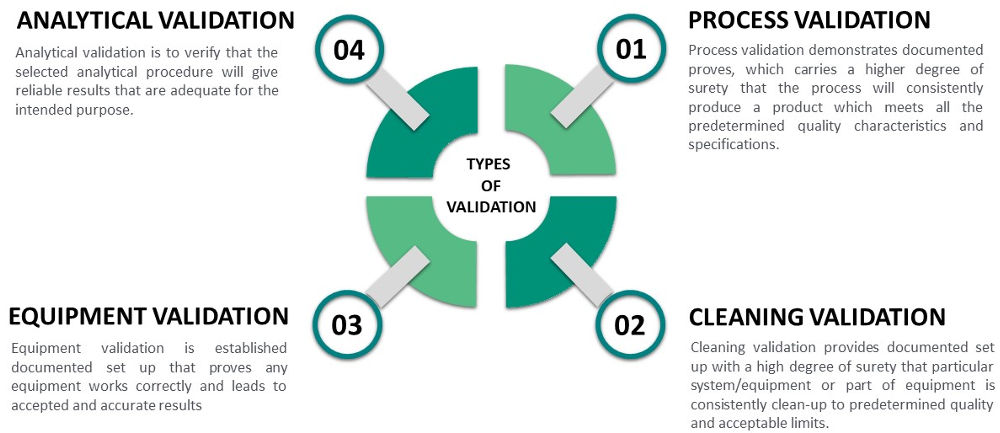

Validation

Establishing the documented evidence which provides a high degree of assurance that a specific process will consistently produce a product of predetermined specification and quality attributes.

FAT & Validation

FAT & Validation is not just beneficial for the manufacturer but also for the end user as well. Rectifying issues while the system is still in the possession of the OEM or installed in the facility helps to keep the project on track and within budget. In conventional projects, FAT & Validation are time-consuming activities, however in Modular Mobile Facility there is an advantage to perform FAT of the equipment & Validation of the process before the facility is shipped to the end user.

Errors or deviations during installation of the equipment's are significantly reduced in MMF, thereby minimising the time required to construct the facility. Pre-validating the facility helps to determine the worst-case situation & risk that may arise during the manufacturing of a quality product and decreases the risk of noncompliance regulatory. MMF ensure to maintain the quality standards and existing cGMP requirements for manufacturing operations.

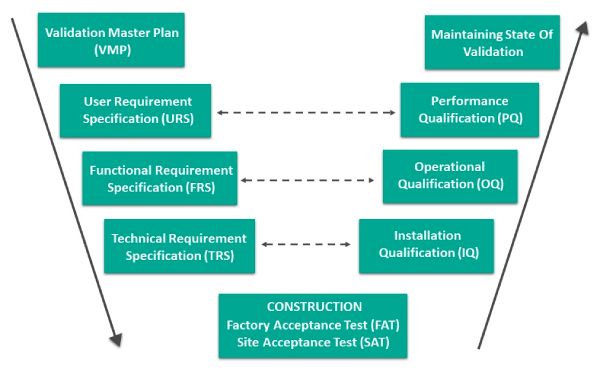

Standard V Model

In MMF we use the GMP standard V model to qualify and acquire documented evidence that the equipment, facility, and system is fit for operation. The V cycle in its pharmaceutical form allows a sequence of steps to cover the different stages of validation in terms of traceability on a 4Q model (DQ, IQ, OQ, PQ), with the notion of protocol, tests, and report. This allows us to have the writing of what we should do, do what we wrote, and write what we did. Validation documentation is essential to maintain the quality standard of the facility it acts as a proof in the case of audit or inspection.